Fusion

Welding

Established in 2011, Solo Fusion Welding is New Zealand's leading provider of welding solutions.

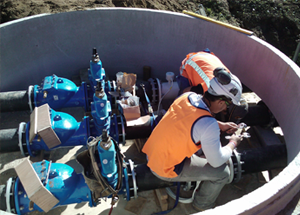

Fusion Welding’s premier site solutions team partners with New Zealand’s top civil contractors to deliver cutting-edge civil infrastructure projects nationwide. Renowned for excellence, Solo Fusion Welding boasts one of the largest and most advanced welding and best-equipped on-site custom plastic welding teams in the country.

Our seamless collaboration with the heavy fabrication department ensures the seamless integration of complex offsite fabrication, optimizing efficiency and precision on every welding project.

Book your site welding services

Contact usMeet Our Fusion Welding Team

We have invested extensively in our people, technology and hardware to ensure that we can meet the specific needs of your site. We offer electrofusion (E/F), butt-welding and extrusion welding services for PE Pipe as well as site modifications for PVC and PE tanks and componentry.

Qualifications and Training

- HSK Extruder training on Welding of thermoplastic sheets according to DVS 2207-4

- HSK Extruder training on Welding in accordance with DVS 2207-4 using Hot Air Extrusion Welders from HSK

Kunststoff Schweißtechnik GmbH. - HSK Extruder training on Practical extrusion welding training on Agru HDPE Ultra-grip concrete protective

liner. - Safety ‘n Action Confined Space and Gas Detection Refresher.

- Safety ‘n Action Height Safety Advanced

- J.WALL Ltd Butt Fusion Accreditation

- J.WALL Ltd Electrofusion Accreditation

- SITEWISE

- Telarc

- Tōtika

- Construct Safe

- First aid

Commitment to Excellence in Welding Solutions

Solo collaborates with local New Zealand authorities, international civil construction companies, and communities across the Asia Pacific to enhance infrastructure in Pacific Island nations. Our site welding teams are dedicated to providing reliable and durable solutions that contribute to the growth and development of these regions.

Our welding processes adhere strictly to ASNZS 4645.3.2018 standards, ensuring the longevity and reliability of our work. We maintain the highest standards of welding excellence, including ISO 21307:2017, which specifically addresses the butt fusion jointing of polyethylene (PE) pipes and fittings. This international standard guarantees that our welding practices meet rigorous quality and integrity requirements.

By complying with both ISO 21307:2017 and ASNZS 4645.3.2018, the Australian/New Zealand standard for on-site butt welding of polyethylene pipes, we ensure that our procedures not only meet local regulatory standards but also align with international best practices. This commitment assures the durability and reliability of every project we undertake.

Butt Welding

Solo Fusion Welding's butt-welding teams specialize in welding PE pipes of up to 2 meters in diameter, whether in trench or above-ground installations.

With extensive experience in assisting with PE pipe installations across New Zealand and the Asia Pacific, our teams excel at addressing site-specific challenges encountered in real-world scenarios. Collaborating closely with major civil engineering contractors, we ensure that all projects are executed efficiently and on schedule.

Electrofusion Welding

Electrofusion (E/F) welding is deceptively challenging. While acquiring a qualification in E/F welding may seem straightforward, achieving clean and precise welds, particularly in large diameters and in compliance with the ASNZS 4645.3.2018 standard, requires significant expertise.

Solo Fusion Welding tackles large and intricate electrofusion welds almost daily. Entrusting such critical tasks to inexperienced alternatives is a risk not worth taking. Choose Solo’s electrofusion pipe welders for reliable results you can trust.

Electrofusion welding often complements our custom fabrication or butt-welding teams. Recognizing that every application is unique, Solo’s expertise ensures the selection of the most suitable welding process for each project.

PE Extrusion Welding

In the modern day, there are very few companies that can weld PE Plastic. There are even fewer companies that have the skill set and the equipment to conduct on-site extrusion welding of heavy gauge PE Piping for the Civil Construction sector.

Our PE welding is completed in line with DVS 2208: Welding of thermoplastics – Extrusion welding of thermoplastics. DVS 2207-11: Welding of thermoplastics – Welding extruded sheets and films of thermoplastics.

Solo Fusion Welding stands out as one of the select few companies in the Asia Pacific region with the expertise required for this specialized work.

Consequently, our services are in high demand. Our highly skilled team is relied upon by the broader civil sector to ensure that projects are executed to the most exacting standards.

Onsite Welding

Timely, efficient, and cost-effective site installation is essential for the success of any civil infrastructure project.

With decades of experience, Solo Fusion Welding has established itself as a trusted partner to all major players in the New Zealand civil infrastructure industry.

We have cultivated strong relationships with a wide spectrum of stakeholders, ranging from local government authorities to structural engineers and machinery operators. These partnerships enable us to provide comprehensive support throughout every stage of your site project, up to completion.

Onsite Modifications

Solo Fusion Welding's versatility shines through in our capability to perform onsite modifications. We excel at adapting standard items to suit unique circumstances, ensuring seamless integration into your project.

Utilizing a combination of off-site and on-site fabrication, gaskets, electrofusion welding, and innovative problem-solving, we expertly install PE and PVC pipe, and fittings tailored to the specific requirements of your location or needs.

A common request involves modifying or “fitting out” water or chemical tanks. Solo possesses the rare ability to execute this work efficiently, even in tight or challenging locations, delivering quick and effective solutions.

Solo Fusion Welding - Projects

A sample of our capabilities.

New Zealand

Northland Region

- Kaitaia – DN355mm – Butt Weld

- Kerikeri Project – DN710mm – Butt Weld and Electrofusion Weld

- Parua Bay – DN180mm – Butt Weld and Electrofusion Weld

- Niwa King Fish Farm – DN1200/900mm – Butt Weld, Electrofusion Weld, Extrusion Weld

- Ngawha Springs – DN1000mm – Butt Weld

Auckland Region

- Auckland Domain – DN400mm – Butt Weld

- St Mary’s Bay Outfall – PE liner 1800dia – Extrusion Welding

- St Mary’s Bay Outfall – DN1600mm – Butt Welding

- Clevedon Water – DN355/250mm – Butt Weld & Electrofusion Welding

- Hobsonville – DN1000/630mm – Butt Weld

- Mairangi Bay Rising Main – DN800mm – Butt Weld and Electrofusion Weld

- West Harbour – DN710mm – Butt Weld

- Wairau Road – DN1000mm – Butt Weld

- View/Wairau Road – DN1000mm – Butt Weld

- Snells Beach – DN1000mm – Butt Weld and Electrofusion Welding

- BNR Project Mangere – DN1200/800mm – Butt Weld

- Massey Swanson – DN560mm – Butt Weld & Electrofusion Weld

- Massey Swanson – DN710mm – Butt Weld

- Pukekohe – DN1200/1400 – Butt Weld

- Pukekohe – DN180mm – Butt Weld

- Rail Crossing Pukekohe – DN1000mm – Butt Weld

- Central Interceptor – DN1400mm – Butt Weld

- Army Bay – DN800mm – Butt Weld

- Army Bay – DN1100mm – Butt Weld

- Panmure – DN900mm – Butt Welding

- Northern Interceptor – DN710mm – Butt weld

- Micro Tunnel CPL Lining Welding GAJV – Extrusion Welding

Waikato Region

- Waharoa – DN180mm – Butt Weld and Electrofusion Weld

- Steamfields Taupo – DN450mm – Butt Weld

- New Zealand Steel Ltd Taharoa Mine – DN450/500mm – Butt Weld and Electrofusion Weld

- Peacocks Project – DN630mm – Butt Welding and Electrofusion Welding

Bay of Plenty Region

- Hinemoa (Whakatāne) – DN1000mm – Butt Weld

Manawatū-Whanganui Region

- Whanganui WWTP – DN1000mm – Butt Weld

Hawke’s Bay Region

- Hastings Wastewater Outfall Diffuser Replacement – DN900mm – Butt Weld

Taranaki Region

- Hāwera – DN180mm – Butt Weld and Electrofusion Weld

Wellington Region

- Basin Reserve Wellington – DN710mm – Butt Weld

- Dews Construction – DN630/400mm – Drainage – Butt Weld

Solomon Islands

- Solomon Islands Project – DN710/500/400mm – Butt Weld and Extrusion Welding

Let's Chat

Have questions? We’re happy to help.